- View Mobile Number

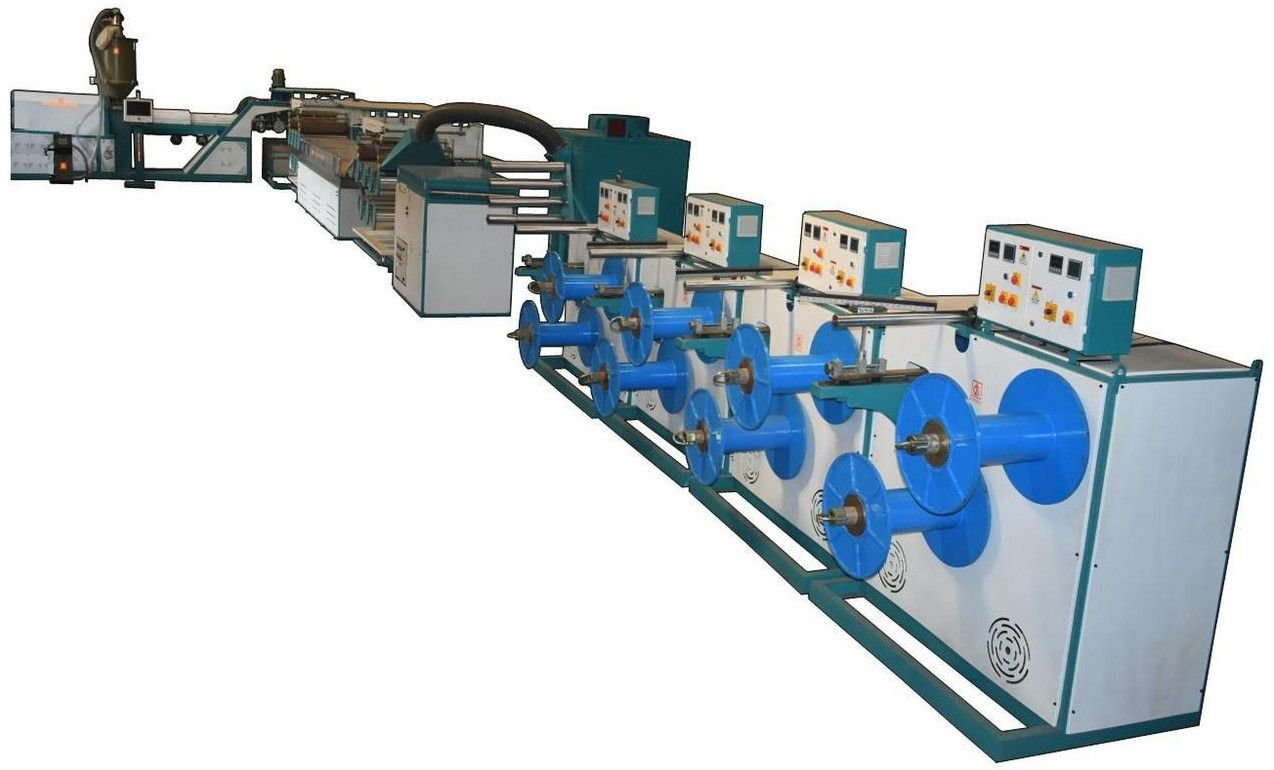

Extrusion Line

Leading Manufacturers, Exporters and Wholesaler of Nylon Monofilament Extrusion Plant, PET Monofilament Extrusion Plant, Polyester Monofilament Extrusion Line, PP Monofilament Extrusion Plant, Nylon Monofilament Extrusion Line, PET Extrusion Line Machine, PP-HDPE Monofilament Extrusion Plant, Danline Monofilament Extrusion Plant, PP Tape Fibrillating Extrusion Plant, PP Sutli Extrusion Plant, PP Box Strapping Plant, Plastic Waste Recycling Line and Mother-Baby Twin Extruder from Bhavnagar.

| Business Type | Manufacturer, Exporter |

| Brand Name | OEM |

| Capacity | 35 to 60kg per hour |

| Machine Type | automatic |

| Business Type | Manufacturer, Exporter |

| Brand Name | OEM |

| Driven Type | Electric |

| Color | Black, Brown, Grey |

| Condition | New |

| Automatic Grade | Automatic, Fully Automatic, Semi Automatic |

| Power | 200kw |

| Certification | CE Certified, ISO 9001:2008 |

| Voltage | 440V |

| Type | Extrusion plant |

| Country of Origin | India |

| Material | PET Flex |

| Business Type | Manufacturer, Exporter, Supplier |

| Usage/Application | High-quality Monofilament Yarn Production |

| Type | Extrusion Line |

| Material | Polyester/ Nylon |

| Condition | New |

| Name | Polyester Monofilament Extrusion Line |

| Major Applications | Fishing Twine,Fishing Net,Zipper,Mosquito Nets,Textile Fiber,Sewing Thread,Tooth Brush,Brush & Brooms,Artificial Hair,Badminton Racquet String,Awning Cloth,Engineering Plastics/Films,Industrial And Marine Ropes,Hose Reinforcement,Agriculture / Horticultur |

| Business Type | Manufacturer, Exporter |

| Brand Name | Shreeji |

| Type | Monofilament plant |

| Material | steel |

| Payment Terms | T/T |

| Delivery Time | 60 days |

-

Scalable Output: From 30 kg/hr (50 mm) to 250 kg/hr (125 mm)—choose the right model based on production targets

-

Material Flexibility: Accepts virgin or reprocessed HDPE and PP

-

Wide Application Range: Ideal for rope, net, brush, and geotextile filament production

-

Export-Ready Build: Heavy-duty MS frame, global shipping support, and strong after-sales service

| Business Type | Manufacturer, Exporter, Supplier |

| Delivery time | 80-90 Working Days |

| Product Service Code | 8477 |

| Line Speed | Max 180mpm |

| Model No | SYN/NMF-55/65/75/80 |

| Plastic Processed | 6 & 6.6 Nylon Granuals |

| Power Consumption | 170hp |

| Machine Type | Manual/ Semi/ Automatic |

| Capacity | Depand On Raw Material Line Speed And Screw Dia, 700kg To 5 Ton Per Day |

| Usage/Application | Bird Net Fish Net Badminton Net Agriculture,Nylon Filament |

| Country of Origin | Make in India |

Discription

We are a leading manufacturer and exporter of advanced Nylon Monofilament Extrusion Plants, designed for diverse applications. Built with cutting-edge technology and high-quality components, these plants produce strong, reliable nylon monofilaments. Perfect for industries like textiles, fishing, protective nets filtration, zipper, automotive, and brush manufacturing, our plants guarantee top performance, efficiency, and adherence to international standards.

Ideal for the yarn production industry, our plants are known for their quiet operation, energy efficiency, and long-lasting performance. Available in various sizes and configurations, they cater to diverse production needs. We offer competitive pricing and ensure prompt delivery to meet your business requirements.

Packaging Details.

As per Customer Requirement we can pack both Simple Loose Packing without additional charges & Wooden Pellet Packing as per minimum charges are extra.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | SHREE JI |

| Plastic Processed | Pet Garanual, Pet Flex, Pet Chips |

| Country of Origin | Make in India |

| Application | Zipper, Industrial Brush, Artificial Hair, Broom, Etc. |

| Capacity | Depand On Raw Material Line Speed and Screw Dia |

| Production Capacity | 700kg to 5 Ton per Day |

| Machine Type | Manual/semi/automatic |

| Power Consumption | 170hp |

| Model No | SYN/PET-75/80/90/100/110/125 |

| Line Speed | Max 180mpm |

| Product Service Code | 8477 |

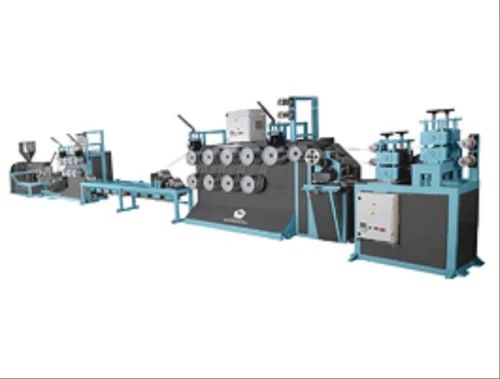

Discription

As a leading manufacturer and exporter, we proudly present our state-of-the-art PET Monofilament Extrusion Plants. Engineered with precision by experienced professionals, these plants utilize the latest engineering technology and high-quality components to deliver exceptional performance. Designed to meet international industry standards, our PET Monofilament Extrusion Plants ensure reliability and efficiency.

Ideal for the yarn production industry, our plants are known for their quiet operation, energy efficiency, and long-lasting performance. Available in various sizes and configurations, they cater to diverse production needs. We offer competitive pricing and ensure prompt delivery to meet your business requirements.

Packaging Details.

As per Customer Requirement we can pack both Simple Loose Packing without additional charges & Wooden Pellet Packing as per minimum charges are extra.

| Business Type | Manufacturer, Exporter, Supplier |

| Product Service Code | 8477 |

| Delivery time | 70-80 Working Days |

| Usage/Application | HDPE Rope, HDPE Fishing Twine, HDPE Filament |

| Line Speed | Max 180mpm |

| Model No | SYN/MF-55/65/75/80/90/100/110/125 |

| Plastic Processed | HDPE, PP, Extrusion Material |

| Power Consumption | 130 |

| Machine Type | Manual/Semi/Automatic |

| Capacity | Depand On Raw Material Line Speed And Screw Dia, 700kg To 5 Ton Per Day |

| Country of Origin | Make in India |

Discription

We are a leading manufacturer and exporter of advanced HDPE Monofilament Extrusion Plants, designed for diverse applications. Built with cutting-edge technology and high-quality components, these plants produce strong, reliable HDPE monofilaments. Perfect for industries like textiles, fishing, filtration, automotive, and brush manufacturing, our plants guarantee top performance, efficiency, and adherence to international standards.

Ideal for the yarn production industry, our plants are known for their quiet operation, energy efficiency, and long-lasting performance. Available in various sizes and configurations, they cater to diverse production needs. We offer competitive pricing and ensure prompt delivery to meet your business requirements.

Packaging Details

As per Customer Requirement we can pack both Simple Loose Packing without additional charges & Wooden Pellet Packing as per minimum charges are extra.

| Business Type | Manufacturer, Exporter, Supplier |

| Delivery time | 70-80 Working Days |

| Product Service Code | 8477 |

| Usage/Application | Heavy Duty Rope, Sea Rope |

| Line Speed | Max 180mpm |

| Model No | SYN/DL-55/65/75/80/90/100/110/125 |

| Plastic Processed | HDPE |

| Power Consumption | 160 |

| Machine Type | Manual/Semi/Automatic |

| Capacity | Depand On Raw Material Line Speed And Screw Dia, 700kg To 5 Ton Per Day |

| Country of Origin | Make in India |

Discription

Shreeji Plastomech is a leading manufacturer of advanced PP Monodanline Extrusion Plants, known for high performance Groove feed technology, energy efficiency, and durability. Our plants produce strong, flexible monodanlines ideal for a wide range of applications, including agriculture, fishing, shipping, construction, and transportation Engineered with cutting-edge technology and built to international standards, our extrusion systems are available in various configurations to suit diverse production needs. We offer competitive pricing, reliable performance, and prompt delivery to support your business growth.

Packaging Details.

As per Customer Requirement we can pack both Simple Loose Packing without additional charges & Wooden Pellet Packing as per minimum charges are extra.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | Make in India |

| Plastic Processed | Pp Raffia, Pp Granual , Pp Extrusion Grade |

| Capacity | Depand On Raw Material Line Speed and Screw Dia |

| Machine Type | Manual/Semi/Automatic |

| Production Capacity | 700kg to 5 Ton per Day |

| Delivery time | 70-80 Working Days |

| Power Consumption | 140 |

| Line Speed | Max 180mpm |

| Usage/Application | Baler Twine,Tape Rope,Net Rope,Fish Net |

| Model No | SYN/TP-55/65/75/80/90/100/110/125 |

| Product Service Code | 8477 |

Discription

We are a premier manufacturer and exporter of advanced Tape Extrusion Line, our tape lines are designed to efficiency and reliably produce premium quality tape line for various applications. Available with either an 75, 80, 90 100 or 110mm screw our products are offers the perfect extrusion solution for any tape production business.

Packaging Details.

As per Customer Requirement we can pack both Simple Loose Packing without additional charges & Wooden Pellet Packing as per minimum charges are extra.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | String,Sutli,Plastic Sutli,Rope |

| Country of Origin | Make in India |

| Capacity | Depand On Raw Material Line Speed and Screw Dia |

| Production Capacity | 700kg to 5 Ton per Day |

| Machine Type | Manual/Semi/Automatic |

| Power consumption | 70hp |

| Plastic Processed | Pp,Rp,Pp Raffia,Next to Vergin, |

| Model No | SYN/DL-55/65/75 |

| Line Speed | Max 140mpm |

| Delivery Time | 60-65 Working Days |

| Product Service Code | 8477 |

Packaging Details

As per Customer Requirement we can pack both Simple Loose Packing without additional charges & Wooden Pellet Packing as per minimum charges are extra.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Packing Strip, Box Packing String, |

| Country of Origin | Make in India |

| Plastic Processed | PP, RP, PP Raffia, Next To Vergin, |

| Capacity | Depand On Raw Material Line Speed and Screw Dia |

| Production Capacity | 700kg to 5 Ton per Day |

| Machine Type | Manual/Semi/Automatic |

| Power Consumption | 140hp |

| Model No | SYN/BS-55/65/75/80/ |

| Line Speed | Max 180mpm |

| Delivery Time | 70-80 Working Days |

| Product Service Code | 8477 |

Packaging Details

As per Customer Requirement we can pack both Simple Loose Packing without additional charges & Wooden Pellet Packing as per minimum charges are extra.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Recycling Equipment |

| Application | Feeding Grinded Plastic Waste To Produce Re-processed Granules For Making Products Like Ropes,Plastic Waste Recycling |

| Design | To Feed Grinded Plastic Waste Efficiently |

| Output | Re-processed Granules |

| Output Usage | Making Products Like Ropes |

| Industry | Recycling |

| Compatibility | Grinded Plastic Waste |

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Extrusion Line |

| Material | Waste Recycling |

| Components | Two Extruders, Two Screen Changers, Die, Die Face Cutter |

| Control System | Electric Panels |

| Quality | High-quality Granules |

| Synchronization | Duly Synchronized |

| Maximum Throughput | Industry Standard |